This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

How to Avoid Battery Hazards: BMS Safety & Security Solutions

Andrey Solovev

Chief Technology Officer, PhD in Physics and Mathematics

Anna Petrova

Writer With Expertise in Covering Electronics Design Topics

A battery management system (BMS) should be all eyes and ears of a battery. It must keep a lookout, take precautions, and protect it from all possible mishappenings. With regard to battery safety and security, common BMS duties include voltage and current control, thermal management solutions, fire protection, and cybersecurity. This post elaborates on the main hazards that can cross a battery’s path and how a BMS can overcome them.

A BMS on Guard of Your Battery

A rechargeable battery is a key element of every battery energy storage system (BESS). But this is also a rather sophisticated and unstable component that needs careful treatment and constant attention. But how can you provide all that?

A BMS is the answer. This system is in charge of multiple functions, and all of them aim to get the most out of your battery within the longest possible time.

For example, by measuring the state-of-charge and state-of-health, a BMS can extend the battery life and improve its performance. By estimating the state-of-energy and state-of-power and balancing cells inside a battery pack, it can harness the full potential of the battery and consequently your battery energy storage system.

Depending on their electrochemistry, batteries can be very sensitive to a changing environment (learn more about different battery technologies used in BESSs). Going beyond the operating limits can be crucial for a battery and may lead to its degradation and untimely death.

More importantly, a battery’s failure can be dangerous to its user. For example, lithium-based batteries are notorious for their inflammability and have a high risk of fires and explosions.

Armed with multiple sensors, modules, and fuses, a BMS can predict potential hazards and safeguard both the battery and the user. A well-thought-out BMS is equipped with battery safety systems that prevent short circuits, ground faults, and thermal runaway. In addition, a BMS security system can ensure safe data transfer and shield your battery storage system from unauthorized use.

A real-time operating system (RTOS) integrated into a BMS allows the system to monitor the battery, identify probable hazards, and fix them in real-time. As a result, you can avoid premature battery replacement as well as costly repair and maintenance of your BESS.

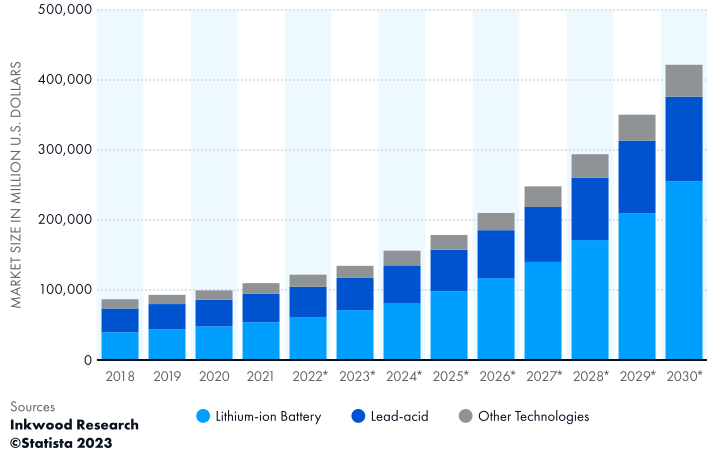

In this article, we’ll focus on a lithium-ion battery—a bestseller in the world of battery energy storage. According to Inkwood Research, lithium-ion batteries will continue to dominate the battery market for at least the next 10 years.

Keep on reading and see what exact precautions you can take when designing your battery management system.

Voltage & Current Control

You can control the battery’s current and voltage in two principals ways: carry out overcurrent and overvoltage protection during charging and avoid undervoltage as you discharge the battery.

The main point: Every battery type has recommended current and voltage limits for both charging and discharging. Here, the battery’s voltage correlates to the state-of-charge or SOC.

For example, it’s best to charge lithium-ion batteries at a voltage not exceeding 4.3 V and discharge them when the voltage is not less than 2.3 V. Charge current for Li-ion chemistries may range from 0.1 C to 1.0 C, and their recommended discharge current is up to 2 C.

Going above or below these limits can cause faulty conditions, such as oxidation and a short circuit, that can seriously damage the battery and cut down on its life span. The worst-case scenarios may include an explosion, fire, and electrical injury.

What you can do about it: You can control your battery’s voltage and current by adding sensors to the cells. The more sensors you add, the higher reliability you can achieve. A BMS will read data from multiple sensors, analyze it, and decide on what to do next.

Thus, if the current, voltage or SOC is over the limit, the BMS can disconnect the circuit using a breaker and stop charging the battery. Similarly, the BMS will react to the undervoltage in case of overdischarging. If the battery’s voltage or SOC drops below the threshold, the system will break the circuit and stop discharging.

Alerting a user to the battery’s out-of-tolerance condition would be a nice and helpful feature to add to your BMS. The system may send an alarm or push notification and display it on the BMS dashboard of a connected device.

To implement overcurrent and overvoltage protection, battery management systems along with chargers can take to constant voltage/constant current battery charging method. The idea is:

You charge the battery with constant current until the battery comes up to a specified voltage level. Then, you charge the battery with constant voltage while the current goes down. Charging will be complete once the current hits the lowest possible reading.

You can introduce voltage and current control at both the software and hardware levels of your battery management system. For example, the basic hardware that we used for an industrial BMS solution comprises:

- current and voltage transformers;

- an amplifier and a buffer with a resistive divider that increase the magnitude of the output current and voltage respectively;

- an analog-to-digital converter (ADC) that converts the current and voltage values to digital signals;

- a microcontroller (MCU) that reads the signals.

The firmware that we wrote for the MCU compares measured values with the setpoints a.k.a. current and voltage limits and after that, sends a command to the breaker.

However, you should play it safe when designing protection circuits. Additional electronics may not only raise the BMS cost but have a negative impact on the battery’s performance—increase internal resistance and decrease power. So it’s important to trust your electronic design to professionals. We at Integra know how to build cost-effective safety solutions for lithium-ion battery energy storage without compromising efficiency.

Thermal Management

Thermal management is one of the most critical lithium-ion battery safety precautions you should take in your BMS design. This relates to the battery’s temperature control and goes hand in hand with heating, cooling, and air conditioning.

The main point: Despite the high efficiency of lithium-ion batteries, there’s the flip side of the coin. Lithium is a highly reactive and flammable metal, which can ignite in the blink of an eye on contact with water and air.

So, even a slight temperature rise or minor battery damage may cause thermal runaway and a short circuit, resulting in bursting and burning.

That’s why battery thermal management is literally a matter of life and death for Li-ion-based solutions. The batteries have the following recommended temperatures:

- 0oC to 45oC for charging

- -20oC to 60oC for discharging

- 0oC to 20oC for storing

What you can do about it: A battery thermal management system of your BMS can monitor the compliance of temperatures with preset limits. To measure the temperature inside or outside the battery, you can use temperature sensors or thermistors—semiconductor devices having a strong correlation between temperature and resistance.

As soon as a BMS detects deviations from the specified values, it takes the steps necessary to save the battery, be it over-or undertemperature.

For example, a BMS can employ thermistors and thermal fuses to rescue the battery from overheating while in operation. They will open the circuit and disable the battery if the temperature rises too high.

Most modern BMSs rely on NTC, or negative temperature coefficient, thermistors. They are highly sensitive and can quickly identify any changes in resistance with high accuracy.

For a thermal battery management system, lithium batteries become a major focus of attention when it comes to charging and discharging. First, you need to watch the internal battery’s temperature to prevent thermal runaway and inflammation.

Second, you must protect against adverse environmental conditions. Li-ion batteries are highly intolerant to extreme temperatures and have recommended charge/discharge temperature limits (see them above). Operating over or under the ambient temperature range may lead to battery aging, capacity loss, and complete failure.

A thermal management system can react to any out-of-limit variations. It can either turn off the charger or adjust the temperature accordingly using a battery fan, cooling system, or heating, ventilation, and air conditioning system (HVAC).

Heat dissipation is of one the methods applied by a BMS to remove excess heat generated from electrochemical reactions running in a battery. This comprises air and liquid cooling, as well as air and fluid convection. Other ways of heat transfer, such as conduction, convection, radiation, and phase changes, may come useful too.

Apart from battery temperature control, you need to ensure the thermal management of electronics engaged in your BMS solution. Installing a sufficient number of thermistors and thermostats can shield your system and its user from possible thermal hazards.

Fire Protection

If your system failed (better not) and the battery caught fire, it must instantly alert you and take immediate measures to nip it in the bud. So, if you cannot stave off battery overheating and the worst comes to the worst, make certain that your BMS has a solid fire protection system.

The main point: For a lithium battery energy storage system, fire is one of the hardest, though not hidden threats.

Knowing the inflammable nature of this battery technology, you can allow for that in your BMS design and take all appropriate steps to prevent probable risks.

However, even if you take care of voltage, current, and temperature control, you cannot guard against battery self-ignition that may happen because of manufacturing defects.

For example, the flaws in cell package and battery plates can lead to internal short circuits and, as a result, sparking, smoking, and burning.

What you can do about it: For starters, make sure your battery is fine. The hazard assessment of lithium-ion battery energy storage systems must include a thorough inspection of the battery, including its package, components, and construction. For example, Li-ion battery manufacturers use separators and flame retardants that prevent thermal runaway and short circuits in the battery.

Proper installation, use, maintenance, and storage can also reduce the risk of battery combustion. Following the conditions listed above, such as current, voltage, and temperature limits, can help you avoid overheating and inflammation of your Li-ion battery.

That said, making a reliable fire protection system can defend you and your BESS from the spread of smoke, fire, and toxic gases.

Placing smoke detectors enables a BMS to detect the combustion of a battery and tap into cell cooling and fire extinguishing systems in good time.

In one of our projects, we installed a smoke detector in each battery module. In case of emergency, the sensor sent a signal to the BMS, and the system opened a valve connected to the pipe of a plumbing system. Also, we set up a water leak detector that detects, controls, and manages pipeline leakage.

It is worth noting that fire safety measures depend on the BMS size. Fire protection measures for smartphones include choosing a quality battery, the correct mode of operation, and protection against overheating.

If we are talking about large-scale systems such as BESS, they must be equipped with sophisticated smoke detection systems, fire extinguishing systems, etc. The more complex the BMS, the more strict its firefighting elements are.

Fire safety is critical to certifying your battery energy storage system. UL, NFPA, and other certification standards set certain requirements that you need to meet to bring your system to market (learn what else you need to consider when building a BESS).

We can help you fail-safe your battery storage system by creating robust software and hardware BMS solutions compliant with international fire prevention and protection regulations.

Cybersecurity

Saving a battery from operating out of limits is not the only concern a BMS can address. Apart from getting a damaged or dead battery, you’d likely be unwilling to have your system attacked or data stolen. So when designing a battery energy storage system, remember to think about its cybersecurity.

The main point: No secret that plenty of BESSs belong to the Internet of Things solutions. Internet connections enable users to monitor and manage their systems remotely from their mobile and other portable devices.

And wherever data transfer is involved, there is always a risk of a breach of confidentiality and integrity. So a BESS can also be prone to cyberattacks.

Without strong BMS security features, the system is not immune to unauthorized access and diverse malicious activities that can seriously harm the battery and related BESS components.

What you can do about it: You can secure your system by implementing a variety of protection procedures.

First off, you need to take care that only allowed users can access the system as well as modify it. To that end, you can add a user identification system with unique passwords and/or other authentication techniques.

In a custom BMS that we built for one of our clients, users send authentication requests, entering a login and a password. After successful authentication, the users get automatically authorized. They also receive an access rights list used to verify what is permitted to them and what is not. After that, every subsequent request sent from the users is checked for their permissions.

To provide data integrity and security, make sure the communication protocol you use has reliable encryption mechanisms. Thus, a BMS can safeguard any interactions between the elements of the system, keeping the information about the BESS and its user confidential.

Component selection is a key point in BMS design since defective or counterfeit components can cause vulnerabilities in the system’s security. Developing battery management systems, we pay careful attention to the choice of chips, modules, sensors, and other parts that make up the BMS hardware. We opt for high-quality electronic components and write rugged firmware resistant to malware and other security threats.

Conclusion

Reactions initiated by chemical battery species can trigger unpredictable and hazardous effects on both a BESS and its user.

Lithium battery energy storage systems are high on the list of potentially dangerous solutions. So ensuring battery safety is one of the core functions that need implementing in their battery management systems.

A BMS can shield the battery from a range of hazards. Common lithium battery safety challenges comprise:

- Under and overvoltage

- Overcurrent

- Under and overtemperature

- Spontaneous ignition

In addition, a BMS can address security issues, such as cyber threats and loss of confidentiality.

We can help you avert the above troubles by creating full-fledged electronic and software solutions, enabling the long and flawless operation of your battery energy storage system.

Need reliable safety and security systems for your BMS? Drop us a line.

Want to learn more about BMS and BESS systems? Read more on our blog.

Share this article

Related

materials

Battery Management System Development

Integra Sources reviewed the hardware and software of the battery management system. We provided PCB, firmware, app, and server development.

LEARN MORE

LEARN MORE

Battery Management System (BMS): Effective Ways to Measure State-of-Charge and State-of-Health

We’ve picked out tried-and-true methods of estimating the battery’s state-of-charge and state-of-health to share them with you.

LEARN MORE

LEARN MORE

State of Charge and State of Health in Infographics

We've prepared a cool infographic for our SOC and SOH article. Read the previous article and look at this post.

LEARN MORE

LEARN MORE