Avalanche Photodiodes in Distributed Temperature Sensing Systems

Andrey Solovev

Chief Technology Officer, PhD in Physics and Mathematics

Timur Yuldashev

IT Writer, PhD in Philological Sciences

Temperature monitoring solutions are used across various industries, with distributed temperature sensing (DTS) being one of the most promising methods. This technology requires avalanche photodiodes (APDs) that convert light into electrical signals and can measure temperature in fiber optic cables over long distances.

Modern temperature monitoring technologies play a key role in various fields, including the energy sector, oil and gas industry, construction, and environmental monitoring. A range of solutions can be applied depending on the specific requirements of each task: infrared and digital thermometers, thermal imaging cameras, etc. If you need consultation on this matter, please contact our team. We will offer the most optimal solution tailored to the specific needs of your enterprise.

One of the most promising temperature measuring methods is distributed temperature sensing (DTS). This technology enables high-precision and continuous temperature monitoring along the length of fiber optic cables, making it indispensable for real-time monitoring of infrastructure health and processes.

Important components of DTS systems are avalanche photodiodes (APDs). These devices provide high sensitivity and fast response to temperature changes. They can efficiently convert optical signals into electrical signals, providing accurate temperature data collected over distances of 30 kilometers or more.

In this article, we are going to compare various avalanche photodiodes used in DTS solutions.

What are Avalanche Photodiodes?

There are two main types of devices used for converting light into electrical signals: PIN photodiodes and avalanche photodiodes. They have different structures and operating principles.

Avalanche photodiodes (APDs) are semiconductor devices that convert light into electrical signals through the photoelectric effect. They can be considered as highly sensitive photodetectors.

These devices have greater sensitivity compared to other semiconductor photodetectors, which allows them to be used for detecting low luminosity levels (≲ 1 nW).

The main advantages of avalanche photodiodes compared to PIN photodiodes are:

- High sensitivity

- Low noise levels

- Short response time

- Wide bandwidth

The latter manifests itself as the ability to register waves ranging from 400 to 1700 nm, which exceeds the capabilities of PIN photodiodes. For comparison, silicon PIN diodes operate in the range of 400 to 1100 nm, covering the visible and near-infrared spectrum. Germanium and gallium-indium-arsenide PIN photodiodes have ranges of 800-1600 nm and 1000-1650 nm, respectively.

The reaction time of APDs is limited by the charge carrier transit time and the RC time constant. The reaction time of avalanche diodes is about several tenths of a nanosecond. In some cases, it can be reduced to less than 100 picoseconds, which is several times shorter compared to standard PIN diodes.

The higher the reaction speed, the greater the spatial resolution of the diode. In the case of thermometry systems, this allows sensors to detect local overheating that exceeds acceptable limits. Low-speed photodiodes (that have lower resolution) either register insignificant deviations over relatively long sections or do not register temperature changes at all. As a result, dangerous temperature rises or even fires may be detected too late.

These features of avalanche photodiodes are crucial for the energy sector, oil and gas industry, chemical industry, aviation, and other fields. DTS systems are used for temperature monitoring in high-voltage transformers and power lines, in oil and gas wells, during chemical processes, and for tracking temperature deformations in aircraft bodies.

Key Characteristics of Avalanche Photodiodes

Photodetectors are installed in control and measurement equipment, fiber-optic communication line sensors, and cable television systems. They are used for monitoring systems and analyzing polarization.

When it comes to avalanche photodiodes in distributed temperature sensing systems, it is crucial for them to provide a rapid response to changes in the received optical power. The next paragraphs briefly describe the operating principle of this system and explain what parameters are most important for this type of measurement equipment.

Temperature is recorded along the optical line of the sensor, i.e., it is measured continuously rather than at discrete points. Typically, DTS systems can measure temperature with a spatial resolution of 1 meter and an accuracy of ±1°C. Measurements can be taken over distances exceeding 30 km, and some specialized systems can provide even more precise spatial resolutions. Thermal changes along the optical fiber cause local variations in the refraction index, which in turn leads to inelastic scattering of the light traveling through it.

The measurement principle is based on the Raman effect. Chandrasekhara Venkata Raman was an Indian physicist specializing in optics and acoustics. During his journey from London to India, he became interested in why the Mediterranean Sea appears blue. At that time, it was believed that water simply reflects the color of the sky. However, this explanation did not satisfy Raman. Later, he conducted experiments that showed that when light hits the molecules of a substance, most of the light is scattered without changing its wavelength. This is known as Rayleigh scattering. However, a small portion of the light is scattered with a change in wavelength, which is related to the vibrations of the substance's molecules. This phenomenon was named the Raman effect. The scientist was awarded the Nobel Prize in Physics in 1930 for this discovery. Today, the Raman effect is used for chemical analysis, studying the composition and structure of substances, as well as in DTS systems.

Due to heating or cooling, the physical dimensions of the fiber change, which causes local changes in the light transmittance characteristics. As a result of light extinction in quartz glass fiber due to dispersion, it is possible to determine the location of an external physical effect, allowing the optical fiber to be used as a linear sensor.

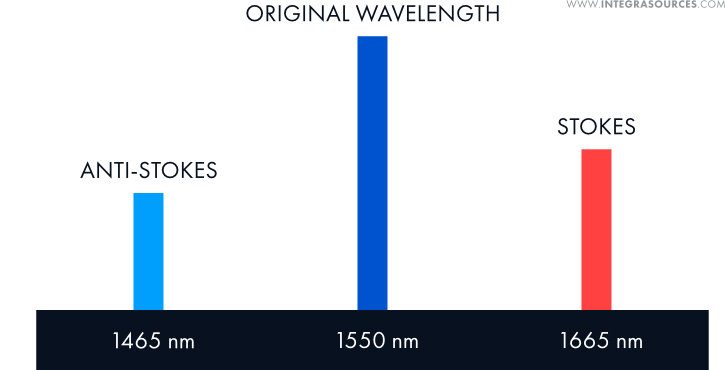

Optical fiber is made from doped quartz glass, which is a form of silicon dioxide (SiO2) with an amorphous solid structure. Thermal effects cause lattice vibrations within the solid body. When light falls on these thermally excited molecular vibrations, photons and the electrons of the molecules interact. This causes light dispersion in the optical fiber, also known as combinational scattering or Raman scattering. Unlike the incident light, this scattered light experiences a spectral shift equivalent to the resonance frequency of the lattice vibrations. The light scattered back from the optical fiber contains three distinct spectral components:

- Rayleigh scattering of the same wavelength as that of the laser source;

- Stokes line components from photons are shifted towards longer wavelengths (lower frequencies);

- Anti-Stokes line components, with photons shifted towards shorter wavelengths (higher frequencies) than Rayleigh scattering.

The distribution of wavelengths for anti-Stokes and Stokes Raman scattering

Temperature has a strong influence on the intensity of the so-called anti-Stokes band, while the characteristics of the so-called Stokes band are not affected by temperature. Thus, it is possible to calculate the local temperature of the optical fiber from the ratio of anti-Stokes and Stokes light.

For accurate measurements, the system requires photodiodes to operate in the range of 1440-1700 nm.

There are two main types of avalanche photodiodes: those based on germanium and those based on gallium arsenide.

- The first type is made from germanium. It can “see” infrared radiation well (wavelengths up to 1.7 µm) but operates with some noise.

- The second type is made from gallium arsenide. It can detect slightly further into the infrared spectrum (up to 1.8 µm) and operates more cleanly, with less interference.

Modern versions of gallium arsenide detectors are made multilayered, with the addition of other materials to enhance their characteristics. They typically have indium phosphide as a substrate and a second layer to create a heterostructure. Indium gallium arsenide (InGaAs) has a high absorption coefficient at the wavelengths commonly used in fiber optic communication lines. Therefore, even micron-thick layers of InGaAs are sufficient for complete absorption of the radiation.

These materials provide low latency and noise levels and can be used to create devices with a bandwidth of over 100 GHz (in the case of simple InP/InGaAs systems) or up to 400 GHz (in the case of InGaAs in a silicon-based heterostructure). Thus, the data transmission speed of such devices can exceed 10 Gbps.

Another important characteristic of distributed sensors is spatial resolution, i.e., their ability to distinguish the value of the measured quantity at closely spaced points.

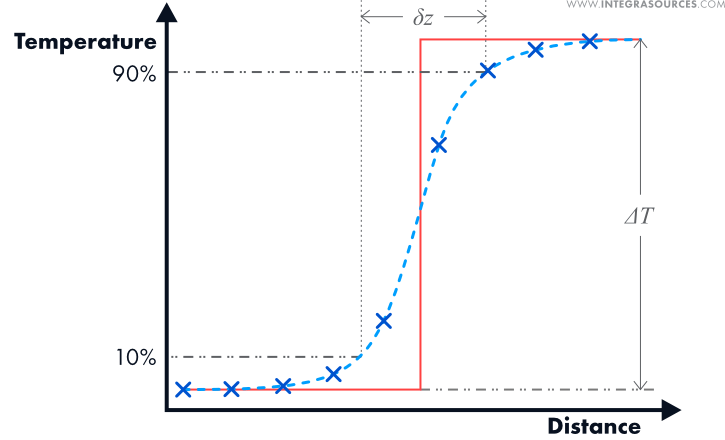

Typically, a distributed sensor responds to an abrupt change in the measurand (temperature) along the fiber with some blurring of that edge in its output. The figure below illustrates the difference between the actual measured quantity (solid line) and that detected by the sensor (dashed line). The spatial resolution δz is usually defined as the distance over which the sensor output corresponds to a sharp transition from 10% to 90% of the fiber optic temperature value.

These values (10%–90%) are appropriate for determining the degree to which a transition is reproduced by the sensor.

Method for measuring spatial resolution in distributed sensors

When selecting photodiodes for DTS systems, one should also consider other parameters: market availability, bandwidth, the dependence of output signal parameters on the photodiode's own temperature, etc. However, the most important parameters of APDs are the response speed and, consequently, the spatial resolution.

Testing avalanche photodiodes

In electronics design, we often resort to testing various components or concepts. This is necessary to assess their functionality and identify potential problems at early stages, when it is difficult to tell if the chosen approach is effective. The Integra Sources engineers are ready to assist in assessing the feasibility of your concept and selecting the optimal technical solution.

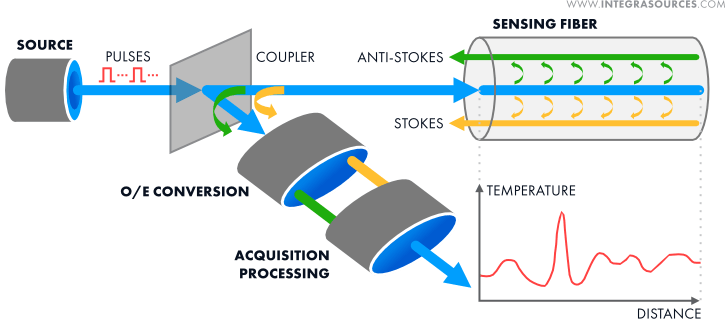

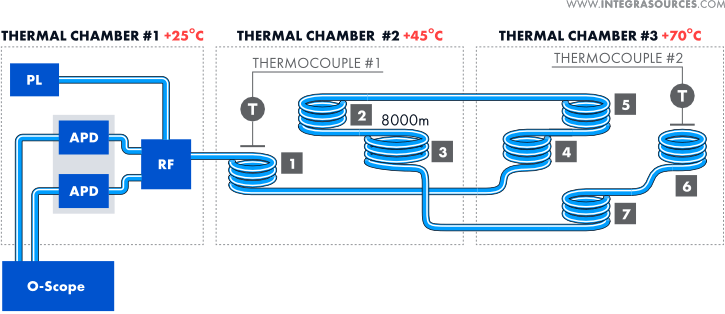

The following setup was used for testing various avalanche photodiodes:

The schematic diagram of the APD testing setup. O-Scope is the digital oscilloscope; thermal chamber 1 contains replaceable boards with photodiodes under test; PL is the pulsed laser; RF is the Raman filter; sections 1, 2, 4, 5, 6, and 7 are optical fiber segments of 100 m each; section 3 is optical fiber of 8000 m in length; thermocouple 1, 2 are reference thermocouples.

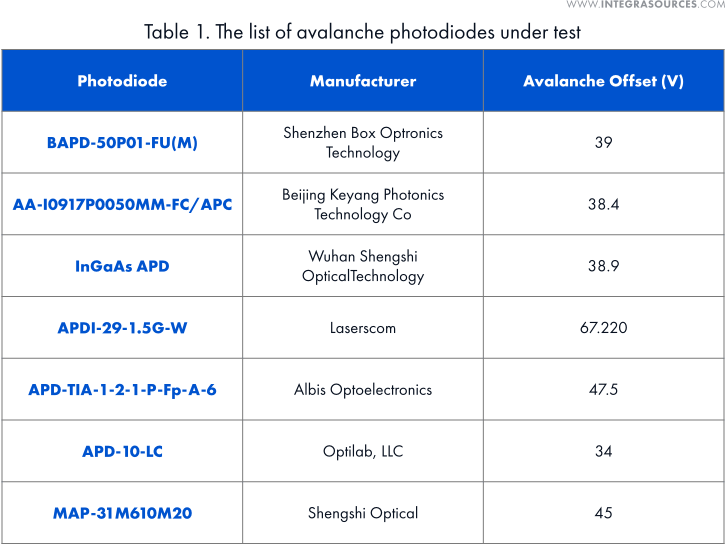

Table 1 contains the list of photodiodes under test. To ensure the reliability of the results, the team tested five pairs of samples of each model.

Light pulses in the optical fiber were generated using a pulsed laser. Pulses with a wavelength of 1550 nm and a duration of 1 nanosecond were used in the testing.

Before conducting the experiment, thermal chambers 2 and 3 were turned on and maintained the specified temperatures (+45℃ and +70℃, respectively) for an extended period. The thermal chamber 1 housing the photodetector board maintained a temperature of +25℃ for 30 minutes prior to tests to establish proper operating conditions.

Due to the Raman effect, light in the optical fiber undergoes stimulated backscattering. The Raman filter separates the spectrum of the reflected light into Stokes and anti-Stokes bands, which are registered by a pair of photodiodes. The signal from the photodiodes is amplified by several stages using operational amplifiers. The output signal from the operational amplifiers goes to the oscilloscope.

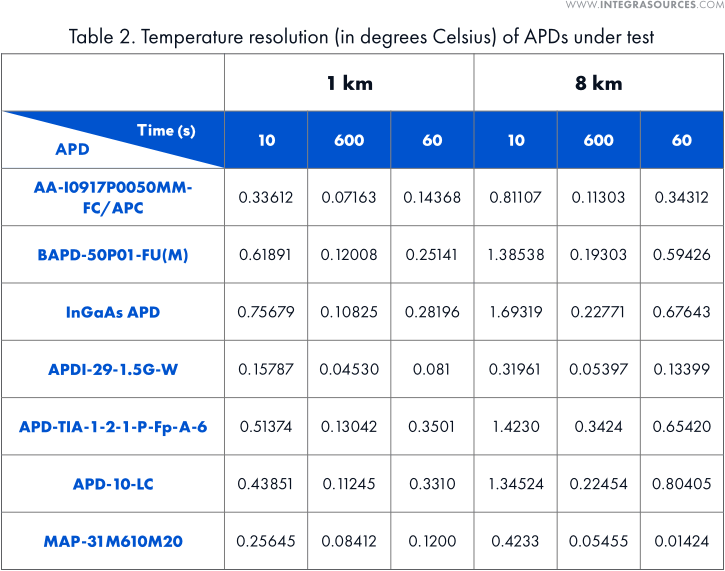

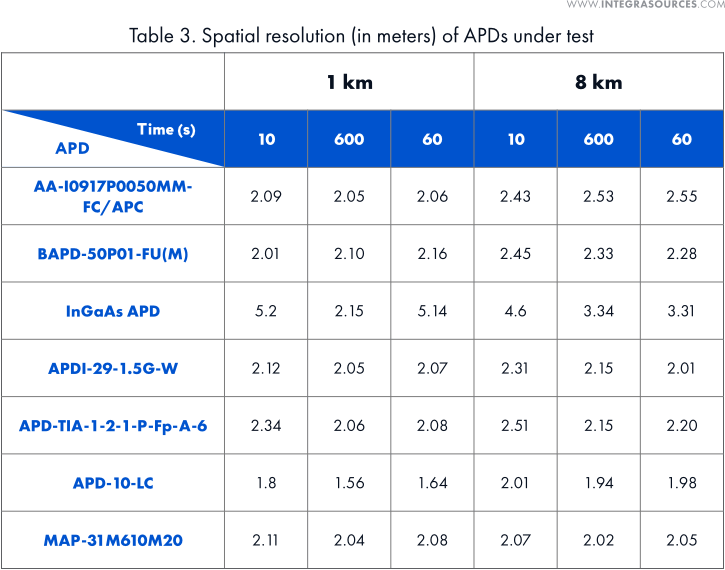

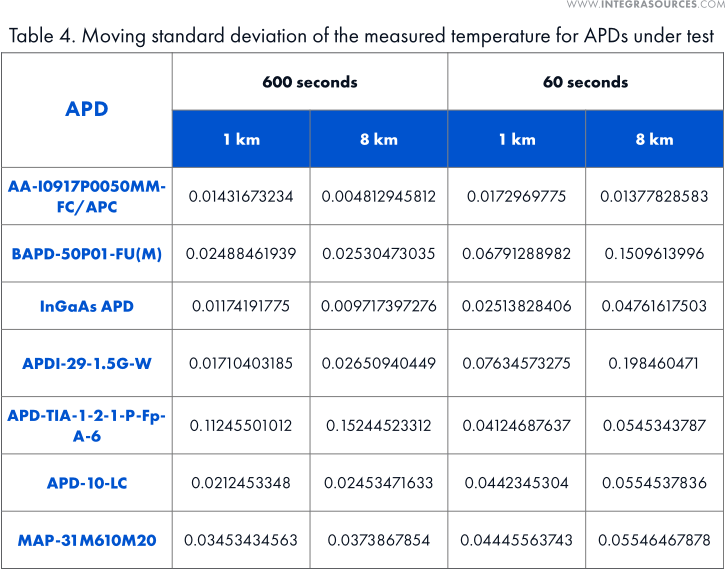

During testing, the team measured the transition time of the electrical signal from 10% to 90% of the transition signal value. This time was then converted into the spatial resolution of the sensor. Temperature resolution was measured as the minimum change in fiber optic temperature that results in a change in the sensor output value. This data was then used to calculate the standard deviation of the measured temperature. We used averaging times of 10, 60, and 600 seconds for measurements.

Table 2 contains the comparison of the temperature resolutions of the APDs under test at lengths of 1 km and 8 km.

We also calculated the spatial resolution of the APDs. The results are shown in the following table.

Lastly, the team calculated the standard deviation of the measured temperature for the tested photodiodes at lengths of 8 km and 1 km for 600 and 60 seconds:

During testing, the most optimal results were shown by the APD-10-LC InGaAs photodiode. It has the best spatial resolution and good temperature resolution. Additionally, the manufacturer provides a precise bias voltage value in the datasheet for the device, which makes it unnecessary to select bias voltage manually and minimizes the risk of damaging the component.

Conclusion

Distributed temperature sensing systems can detect overheating in a timely manner and prevent accidents, which is critical for ensuring safety in industrial facilities. Automated temperature monitoring enhances equipment efficiency and reduces maintenance costs. Accurate temperature measurements help maintain optimal production conditions, which affects the quality of the final product. Lastly, fiber-optic sensors are resistant to external factors, particularly to electromagnetic radiation, which increases the lifespan of monitoring systems.

Important components of DTS systems are avalanche photodiodes (APDs). These are highly sensitive semiconductor devices that convert light into electrical signals through the photoelectric effect. Key parameters of avalanche photodiodes used in DTS systems include a fast response to changes in received optical power and spatial resolution. The tests of various models have shown that the APD-10-LC InGaAs photodiodes perform best in DTS systems.

The Integra Sources team has extensive experience in designing modern solutions for a wide variety of industries. We can help you develop electronics and software for consumer devices, medical equipment, agricultural machinery, industrial solutions, the oil and gas industry, logistics, and more. Contact us, and we will answer any questions.

Share this article

Related

materials

Battery Management System (BMS): Effective Ways to Measure State-of-Charge and State-of-Health

We’ve picked out tried-and-true methods of estimating the battery’s state-of-charge and state-of-health to share them with you.

LEARN MORE

LEARN MORE

Qt and C++ Embedded Development: Pros, Cons, and Alternatives

Learn more about the benefits of using Qt and C++ for embedded systems. We provide a detailed review of popular...

LEARN MORE

LEARN MORE

Starting a Healthcare Electronics Development Project: Key Points You Need to Know

Where to start and what to consider when developing electronics and software for healthcare? Our thorough guide answers all the...

LEARN MORE

LEARN MORE