Industrial App Development: A Silver Bullet to Wipe Out Manufacturing Challenges

Nina Bibikova

IT Writer, Specializes in Electronics and Software Development Topics

Andrey Solovev

Chief Technology Officer, PhD in Physics and Mathematics

- A Few Words About Types of Software

- What Tasks Can Industrial Apps Perform?

- Components of Industrial Application Development

- Key Features of Industrial Applications

- Industrial Cross-Platform Applications: Development Tools and Their Advantages

- Where Are Industrial Solutions Applied?

- The Challenges of Industrial Software Development

- Conclusion

- A Few Words About Types of Software

- What Tasks Can Industrial Apps Perform?

- Components of Industrial Application Development

- Key Features of Industrial Applications

- Industrial Cross-Platform Applications: Development Tools and Their Advantages

- Where Are Industrial Solutions Applied?

- The Challenges of Industrial Software Development

- Formal Approach

- Complexity

- Language-related challenges

- Conclusion

Industry uses software for planning and managing production, logistics, finance, and customer relationships.

The manufacturing app creation process has unique characteristics, and the applications have specific functions.

Below, we consider apps made specifically for the mining, processing, and manufacturing industries: their scope, features, and the benefits of cross-platform app development.

- A Few Words About Types of Software

- What Tasks Can Industrial Apps Perform?

- Components of Industrial Application Development

- Key Features of Industrial Applications

- Industrial Cross-Platform Applications: Development Tools and Their Advantages

- Where Are Industrial Solutions Applied?

- The Challenges of Industrial Software Development

- Formal Approach

- Complexity

- Language-related challenges

- Conclusion

A Few Words About Types of Software

First off, let's brush up on the four main categories of software:

- System software

This can be defined as software that provides a platform for other software and manages hardware and software operations. Examples of system software are Windows, Linux, iOS, Android, etc.

- Programming (auxiliary) software

These utilities serve to write code and to develop, test, and debug other programs. They are assemblers, debuggers, and compilers.

- Device drivers

Drivers manage the peripherals and devices connected to the computer.

- Application software

App software is the largest group of all. It includes mobile, web, and desktop programs that enable end-user to solve specific problems.

This article deals with application software and, more specifically, with a group of applications created for industrial purposes.

If you are seeking expertise in creating industrial solutions, the Integra team is here to provide comprehensive assistance in hardware and software development.

Industrial software solutions occupy a special place in a huge variety of applications. They carry out particular tasks and possess unique features, and creating them requires a software developer’s special knowledge and skills.

What Tasks Can Industrial Apps Perform?

Industrial software applications assist in data collection, processing, management, and controlling manufacturing processes on an industrial scale.

Industrial software performs a wide range of functions in the mining, chemical, energy, oil, gas, and manufacturing industries.

Manufacturing enterprises use software to accomplish various tasks. Here are some of the main ones:

- Preventing equipment breakdown and unplanned downtime

Software applications for industrial solutions help plan preventive maintenance based on the condition of the equipment, the manufacturer's recommendations and the current production situation.

Sometimes, one machine breaking down can bring the line or the entire production process to a standstill. Efficient asset management armed with industrial applications aims to extend equipment life, minimize breakdowns and unplanned downtime, and reduce repair costs.

- Optimizing resource consumption

Better use of any resource, be it raw materials, packaging, energy, or labor, is one way to increase enterprise efficiency. Industrial software collects and processes data, monitors the efficient use of resources, automates processes, and even prevents theft.

Application development costs pay off with interest, returning savings in raw materials, energy, and labor which make up the largest share of the product cost.

Integra Sources has developed a soft and hardware complex for a food manufacturer that consists of devices attached to the equipment. Fitted with temperature sensors, accelerometers, humidity sensors, and gyroscopes, it records equipment conditions and transfers this information to the server via Bluetooth, Wi-Fi, or GSM at defined time intervals around the clock.

Qt cross-platform application development for iOS and Android helped reduce the allotted time for app creation.

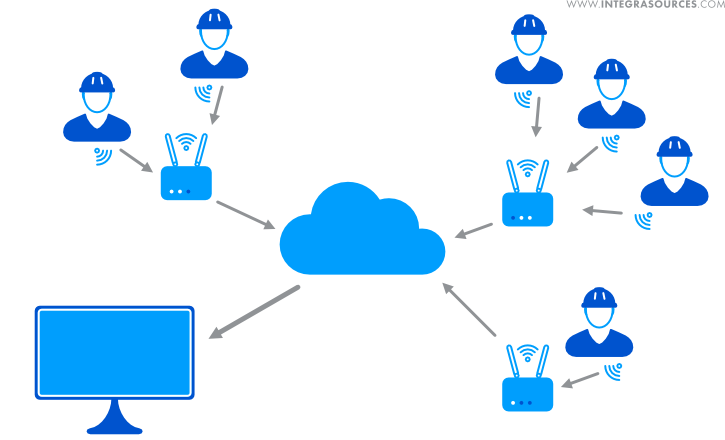

The multi-platform mobile app connected to the web portal collects information from the devices, generates statistics, and sends notifications.

Users can also set allowable ranges of values in the application.

Using applications on their phones and tablets, employees track the operation of the equipment and make timely decisions from anywhere in the shop.

We built the backend for the platform in PHP and used the PostgreSQL database.

The firmware for the device is written in C/C++.

By controlling and preventing sudden fluctuations in the measured parameters, the company has achieved production process optimization and significant energy savings. The quality of products has also improved.

- Quality control

Quality control is not only about checking the final product but also monitoring manufacturing processes and ensuring that standards and requirements are met.

Quality control applications can be based on the use of artificial intelligence to detect defective output, misgrading, and other inconsistencies.

At the request of a manufacturer of precision products, our team has developed an HMI application for identifying marking inconsistencies. Previously, we carried out the project discovery phase, defining development technologies and tools and setting a budget.

The task of the application was to check the conformity of the product and its label using computer vision technologies, including the OpenCV library.

When a mismatch is detected, the operator receives a message on the HMI display. The mislabeled part can then be immediately removed.

- Safety control.

Health and safety management is crucial for any industry but especially manufacturing.

The software trains employees in safety, tracks certificate expiration dates, and monitors employee compliance with all rules and regulations.

Integra Sources has a portfolio of safety-related projects. We have developed a wrist device with a help button for chemical plant workers handling hazardous chemicals. The waterproof bracelet has ultra-low power consumption and can run for two weeks on a 360 mAh Li-ion rechargeable battery.

In an emergency, employees can send a distress signal, transmitted by LoRa or Bluetooth to the nearest gateway. The device’s built-in accelerometer can also detect a worker falling.

The server uses the gateway data to calculate the worker’s exact location. Our software team has also developed a C++ desktop application that displays the data transferred to the backend server via Wi-Fi.

Components of Industrial Application Development

For manufacturing purposes, code development can be different from consumer software development. The need for strict adherence to international standards and requirements for application compatibility with manufacturing equipment brings additional challenges for industrial software developers.

Here are some features of developing applications for industrial needs.

Languages

When developing applications for companies in the mining and processing industries, engineers are limited in their choice of programming language. First, the application must work reliably without failure for long periods. Second, the software must be integrated with the customer's existing software.

At the same time, the application should run on the customer’s chosen device: it might be an iOS or Android smartphone, a Linux or Windows computer, or several devices at once.

In such situations, the obvious solution is to use multi-platform apps that support several operating systems and run on various devices.

Time

Some consumer applications are less demanding on response times and have occasional hiccups. For most users, freezes and unresponsiveness are minor annoyances that they can live with.

Industrial applications, however, often run in real-time, so crashes and hangings are unacceptable. An application for industrial solutions manages operations that must be performed quickly, accurately, and safely.

One of our clients, an IoT development company, has created an industrial hardware device based on the Particle IoT platform that improves the manufacturing process. The device was built using an STM32 microcontroller and is armed with the Particle Wi-Fi module. It receives data on atmospheric pressure, vacuum, temperature, and humidity under the vacuum bag from sensors and transfers it to the user's cloud for processing and storage.

The Qt multi-platform GUI app displays leaks in vacuum bagging tools. It also records all production parameters such as pressure, humidity, and temperature.

Thanks to cross-platform app capabilities, users can quickly access information on a desktop, tablet, or smartphone to respond promptly, seal the bag, and view the curing process.

The device is equipped with an innovative sensor to check the curing of individual parts. When the part curing parameters or temperature threshold are reached, users receive notifications.

The problem was that the application could not provide real-time performance because of the slow data transfer from the cloud. The delay in sending messages was about 250 ms on the server side. Our team has optimized the existing software architecture of Qt cross-platform applications and implemented asynchronous methods on the server, eliminating delays.

Having achieved our objectives, we continue our partnership with the customer to improve the device.

The Integra team has implemented data migration from TinyDB databases to MongoDB databases, Google’s Protocol Buffers, and over-the-air (OTA)C/C++ firmware updates.

Integra Sources continues to cooperate with the customer's company, providing full support for the server, industrial IoT solutions, and user applications. We are also working on adding new features to the software and hardware complex.

Simulation.

Engineers often create software without having physical access to the target device, machines, or line equipment. Emulator programs simulate how the device works to test the app's operation. This additional developer activity requires time and specific skills.

For a software and hardware complex in the mining industry, we had to test the functionality of the Qt cross-platform application that receives data from sensors placed on remote devices. We wrote the BLE-enabled application using C++, QML, and JavaScript.

We faced challenges when it was time to test how the app would operate with the remote sensors because the peripherals were on another continent.

Our developer had written a device emulator program in Swift with toggle buttons simulating the operating mode choice. The BLE application connects to the peripheral and sends commands. The emulator application displays the received request and sends sensor data, simulating the peripheral device operation.

Key Features of Industrial Applications

Mining, processing, and manufacturing companies use custom software to optimize production processes, automate tasks, and improve internal communication.

These are the most common customer requirements when developing applications for industrial automation solutions:

- Software reliability,

- Data security,

- Speed and efficiency,

- Reasonable cost,

- Ease of installation and use,

- Effective data management,

- Integration with internal and external systems,

- Cross-platform capabilities.

System and data security was one of the customer's requirements for our large-scale project, which included industrial HMI app creation.

We differentiated the access rights of app users by defining roles according to the degree of involvement in the equipment management process.

Users with the guest role can only see the options displayed by the app. Employees with the most advanced roles have access to the control screen to manage the equipment.

We have also implemented a one-time password system for one-time login and predefined tasks.

Software solutions for industrial enterprises should be fully integrated into everyday work and bring meaningful benefits.

Industrial app development provides the enterprise with the following advantages:

- Optimal industry-specific IT solutions made precisely for the needs of a particular business;

- Continuous scalability and upgradability of the solution;

- Short time to market;

- Data and applications are under customer control.

Integra Sources creates end-to-end solutions based on customer requirements. We develop bespoke interfaces for managing particular processes. From the very beginning, our solutions are precisely tailored to industrial app requirements.

When developing industrial software application, the outsourcing company should obtain the equipment description with brief technical specifications, certification requirements, and equipment communication protocols.The project can often involve creating both hardware and software. Integra Sources has hardware and software teams. Our engineers have extensive experience and understanding in the hardware and software fields. Read more about hardware development for industrial solutions in our published work.

Software development is becoming more and more complex.

Manufacturing apps are integrated into control systems. Their uses range from controlling individual production processes to managing several enterprises. The more complex the production environment, the more sophisticated the software solutions required to manage it. However, the complexity often comes from permutations of simple combinations rather than complex algorithms.

Today, software is the cement that holds an organization together, whether a small family business or a vast holding company. Companies use bespoke applications for financial tracking and evaluating huge amounts of data, internal communications, data acquisition and processing.

Multi-platform solutions help companies work more efficiently and, therefore, with a higher profit. Automating labor-intensive processes can lead to lower production costs and increased productivity.

Industrial Cross-Platform Applications: Development Tools and Their Advantages

Using cross-platform tools, developers adjust one application to obtain particular benefits for different operating systems:

- Saving time and money spent on product development and gaining an additional competitive advantage;

- With less testing, we can easily make changes and fixes.

- Apps have identical (or close to identical) interfaces on different platforms.

Depending on the project's purpose and scope, programmers use a variety of frameworks and toolkits for cross-platform app development.

In our blog we describe a wide range of tools for multi-platform desktop software creation and cross-platform mobile app development.

Integra Sources’ specialists have extensive experience in C++ and Qt cross-platform desktop and mobile application development.

While staying open to everything new and actively using many other libraries and toolkits, we prefer the Qt framework and C++ for cross-platform app development. In our blog, we discuss Qt's advantages and C++ multi-platform development.

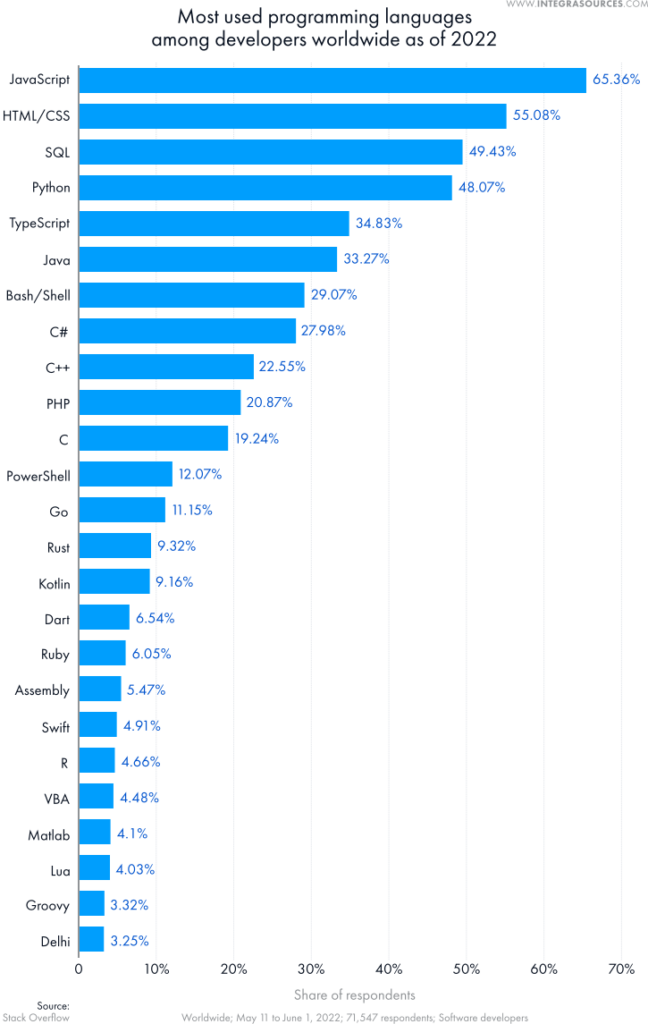

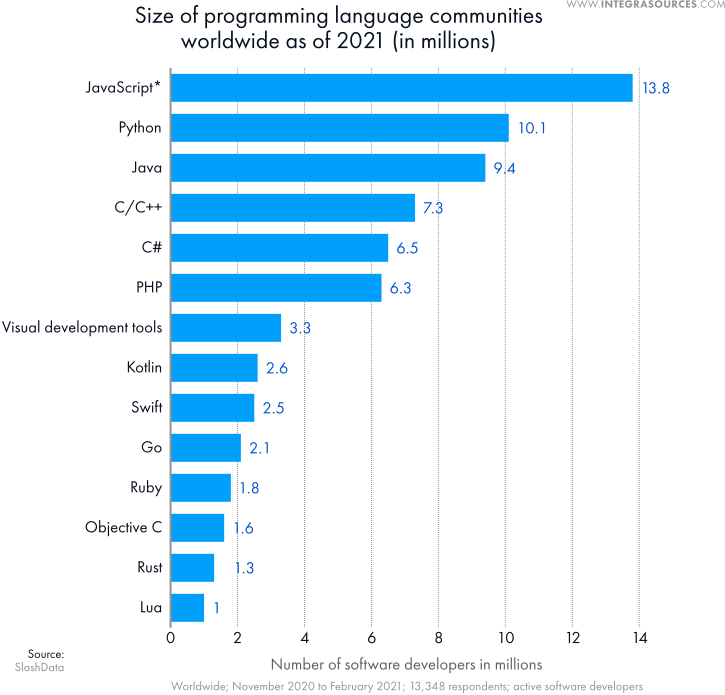

C and C++ are among the most widely used languages for software running in the mechanical engineering, metalworking, manufacturing, and automotive industries. C++ is an object-oriented language that combines high performance with portability. C++ applications are fast and reliable on embedded systems, IoT for manufacturing, and limited hardware.According to Statista, C and C++ are among the top 10 most commonly used programming languages among developers in 2022.

The same source says that C and C++ have the fourth largest community of 7.3 million developers worldwide. This means that most developers’ questions and problems have already been covered and solved by a community of specialists.

C++ is extremely popular for developing applications for embedded systems because it allows you to get the best performance out of the hardware.

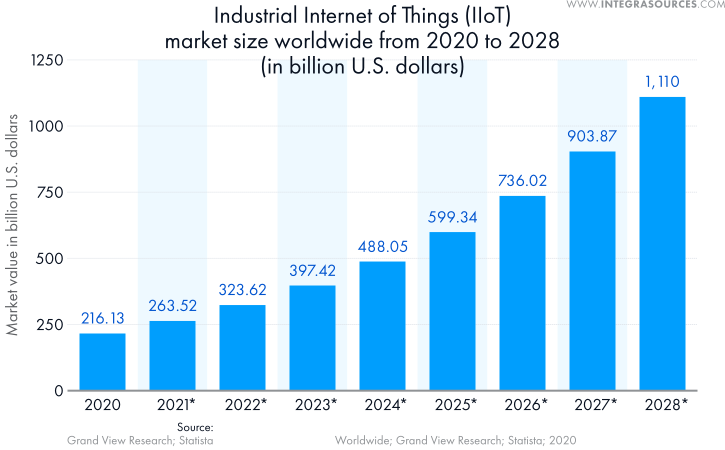

The Internet of Things requires high performance and high-speed processing of large amounts of data. C++ is ideal for these purposes.The Grand View Research and Statista report that the Industrial Internet of Things (IIoT) market will grow more than fivefold from 2020 to 2028, reaching $1.11 trillion.

Not a single manufacturing industry nowadays can do without embedded systems and IoT devices in its production process. C++ is often chosen by manufacturers of industrial automation solutions using embedded systems and industrial internet of things hardware.

Where Are Industrial Solutions Applied?

Software solutions for industrial needs help maintain and manage business processes, improve productivity, and provide production analytics.

Artificial intelligence, machine learning, edge computing, and computer vision are opening up new opportunities for industry-specific IT solutions.

Here are just some areas where software applications are used in industrial solutions.

Improving efficiency in engineering

Design and simulation applications enable businesses to reduce capital and operating costs and automate workflows.

Manufacturing process analysis

Industrial applications help collect, structure, and analyze data related to production processes and provide it in a user-friendly way.

Remote control

Using the web, desktop, or mobile applications, users can control sensors, detectors, and equipment remotely in real time.

Planning

By providing data from various production points, applications can control the flow of raw and packaging materials and manage production planning. A ready-to-use production schedule can be obtained using industrial application software.

Monitoring

Multi-platform monitoring and management apps allow users to combine data from several streams into one source of information and visualize data in the cloud.

Asset efficiency

Industrial applications can help with asset performance management. Company staff uses the software to monitor compliance with regulatory requirements and control costs. Applications make it possible to increase labor productivity, equipment efficiency, and technological indicators.

In most cases, applications perform several tasks or cover multiple business processes.

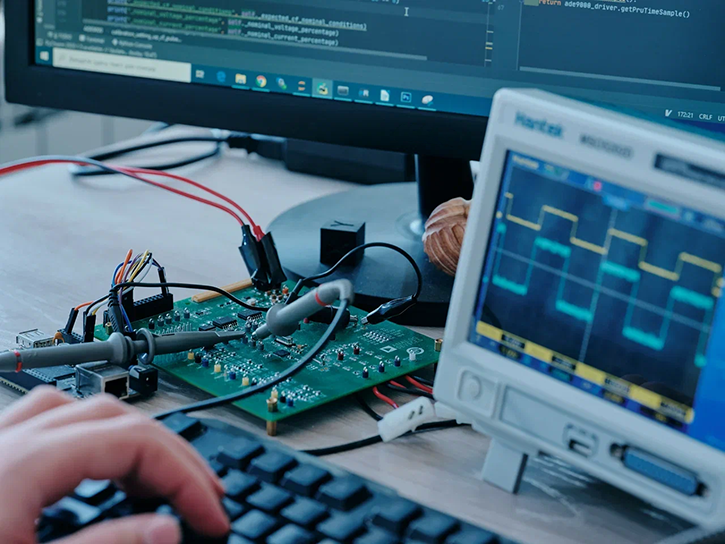

A home appliance manufacturer asked us to implement a software system for its test and measurement instruments to validate the designs and operation modes of devices under test (DUT).

Our development team implemented a test and measurement software system based on a single-board computer (SBC). The SBC controls relays, temperature sensors, a voltmeter, an amperemeter, and a GPIO expander and records the data they collect. The testing results are displayed on a web interface.

Integra's specialists implemented a database system based on PostgreSQL for collecting, handling, and processing data recorded by the SBC with a ZeroMQ socket connection.

We built a web-based Business Intelligence system that displays the data collected from sensors. The GUI part is developed with HTML, CSS, and Javascript. The web UI displays real-time data from monitoring devices and allows users to assign a test scenario to run on several similar devices or to run several test scenarios on one DUT, providing test graphs.

Every second, the sensors attached to the DUT collect up to 10 measurements. A daily graph with test results for each sensor should display from 36,000 to 360,000 points for a 10-hour test. We have optimized the system to provide information without delay.

Our software solution is flexible and reliable enough to work with different home appliances around the clock.

Integra Sources has developed a software package that allows the manufacturer to quickly and accurately test finished products, reducing the cost of returning and replacing defective goods and adding to the company’s positive reputation.

The Challenges of Industrial Software Development

Formal Approach

Corporate applications often have confusing menus, unclear interfaces, and unnecessary functions (or, conversely, a lack of necessary ones). It happens when software updates are untimely or the process takes on a formal character.

Complexity

Complexity is a risk factor in industrial application development.

The following elements can add to the complexity of software and the development process.

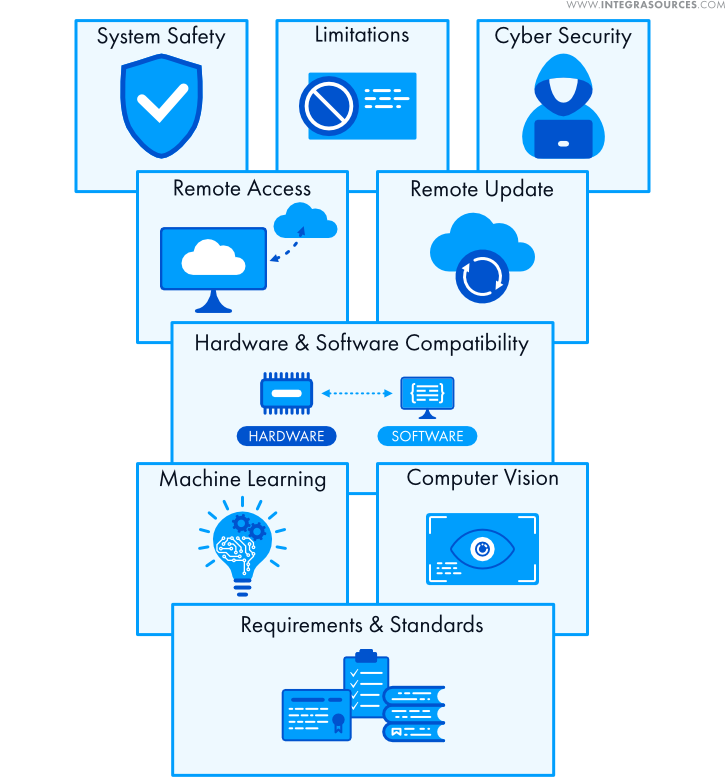

Standards and requirements

Using an industrial application, the engineer can influence the mechanism's operation and control the production process. In this regard, there are requirements for system safety, reliability, and durability.

Systems can become even more complex to meet standards. It's likely to come full circle.

Automation

Sophisticated functions such as machine learning and computer vision process and combine data to provide statistics, predictions, or optimization results. An increase in automation can lead to a more complex structure and hence more complex software.

Interdependence

Applications can communicate with other software inside and outside the system. The consequence is the need to comply with cyber security and provide remote access and updates. These features can add sophistication to the entire system.

Matching hardware and software

Software development and updating should be carried out in parallel with hardware development. The level of hardware should match the software and vice versa. Virtualization can help at some stage, creating, in exchange, extra complexity and requiring additional resources.

Restrictions

Industrial app development is limited by hardware capabilities, manufacturing facilities in general and business opportunities (for example, finance).

Needing to stay within the requirements and provide the necessary functionality, software developers sometimes have no choice but to complicate the system.

In order not to soft-pedal the software updating process and strike a balance in the complexity of manufacturing apps, it's better to entrust industrial software development and further support to professionals with the relevant experience.

Our team at Integra Sources develops software and hardware systems individually according to customer requirements. We strive to make our solutions clear, reliable, and easy to use.

Language-related challenges

Potential security risks are associated with C++ manufacturing app development due to language peculiarities, and open-source software development.

The solution lies in using a standardized process for library management, manual testing in local development environments, or automated testing of C/C++ software.

Conclusion

Companies across a wide range of industries and business areas can benefit from application development.

To improve customer service, streamline operations, and generally stay competitive, businesses should take software development seriously and invest in building applications.

Applications can be deployed to a particular part of a process or extended to the entire production chain.

Industrial solution applications must work with other applications to boost overall cost-effectiveness.

If you are ready to take your business to the next level, contact Integra Sources. We are pleased to help build cross-platform desktop, mobile, or web apps tailored to your needs.

Share this article

Related

materials

Industrial Emergency Detection System

The solution uses artificial intelligence to process images from IP cameras, detect dangerous incidents, and send an alarm to a...

LEARN MORE

LEARN MORE

To Work Like a Clock: App Development for Logistics

Cross-platform app development allows all participants in transport and warehouse processes to timely receive and analyze data and manage logistics...

LEARN MORE

LEARN MORE

Industrial Application Development in Infographics

The functions and characteristics of industrial applications are unique. Employees can monitor and manage production processes from various devices using...

LEARN MORE

LEARN MORE