Temperature and Humidity Monitoring System for Warehouses

Background

Many products, including food, pharmaceuticals, electronics, and chemicals, are highly sensitive to storage conditions. Fluctuations in temperature and humidity can lead to reduced shelf life and decreased quality. Some products such as chemicals, drugs, canned food, or gas cylinders can even become dangerous.

To prevent product spoilage, warehouse owners must maintain optimal conditions and receive timely information about various parameters within the storage area. Modern Internet of Things (IoT) systems can significantly aid in this task.

Request

Integra Sources was approached by an agricultural company seeking a relatively simple and cost-effective solution for monitoring temperature and humidity in their warehouse facilities. The system was required to collect data from sensors installed in the warehouse and transmit the information to a mobile application in real time. In the case of a temperature or humidity violation, the system was required to signal the problem.

Solution

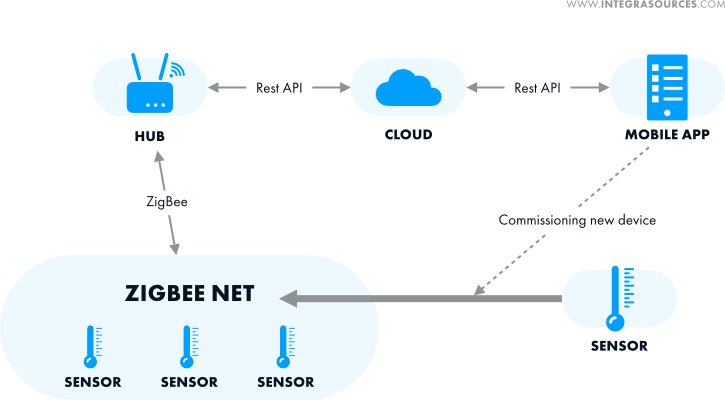

The team designed an Internet of Things system that reads data from ZigBee sensors and sends it to a cloud server via a central hub.

The cloud app processes the data and transmits it to a mobile application. Apart from displaying information for users, the mobile app can be used to connect and disconnect devices from the system.

Temperature and Humidity Sensors

The team chose off-the-shelf ZigBee sensors for this project. These devices offer a wide measurement range, covering temperatures from -40°C to +70°C and humidity levels from 0% to 99.9%. The sensors can be powered by lithium-ion batteries or an external power supply, ensuring flexibility in deployment.

Central Hub

The solution required a central gateway (hub) for transmitting sensor readings to the cloud server. To minimize development costs and leverage existing hardware, we proposed using a Raspberry Pi 3 or 4 as the hub. These single-board computers have more than enough computing power to handle the system's current and future requirements.

The hub acts as a bridge, collecting data from connected sensors and securely sending it to the cloud server via the HTTPS protocol. Upon startup, the hub enters pairing mode. Users can connect to it, using a mobile app via Bluetooth Low Energy (BLE). Once connected, the user can configure internet access for the hub and bind it to their account on the cloud platform, seamlessly integrating the device into the system.

Cloud Application Development

The team developed a cloud application for processing sensor data and configuring the system. It performs several critical functions.

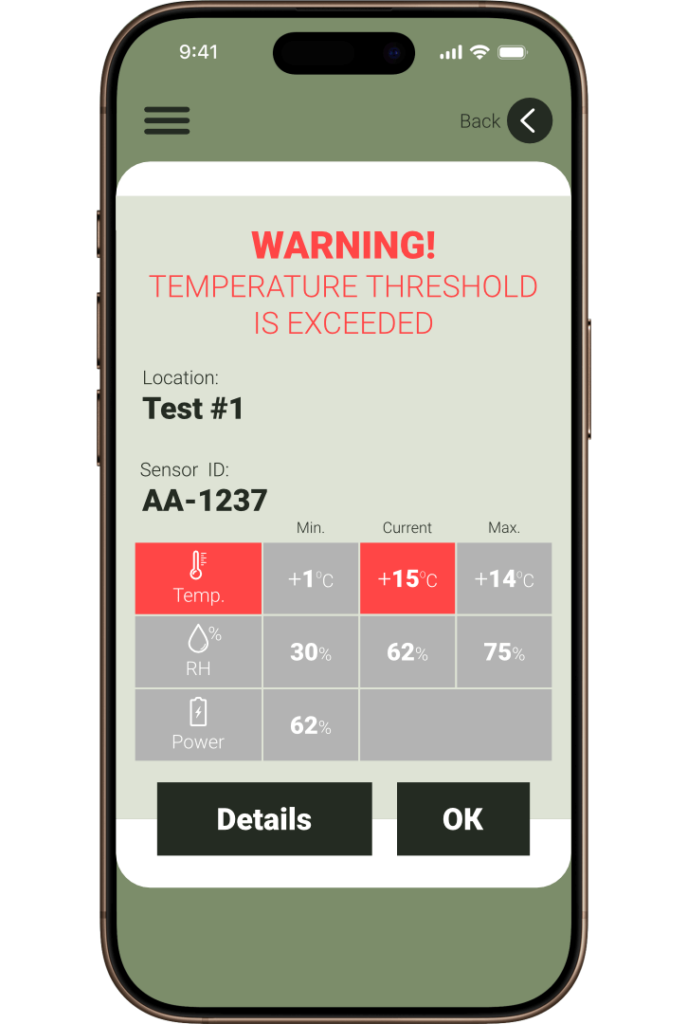

First, the application allows for setting upper and lower limits for temperature and humidity values. If sensor readings exceed or fall below the defined thresholds, the program sends a notification to the user's mobile application. Notifications include the warehouse location and sensor identifier, providing precise information for swift response.

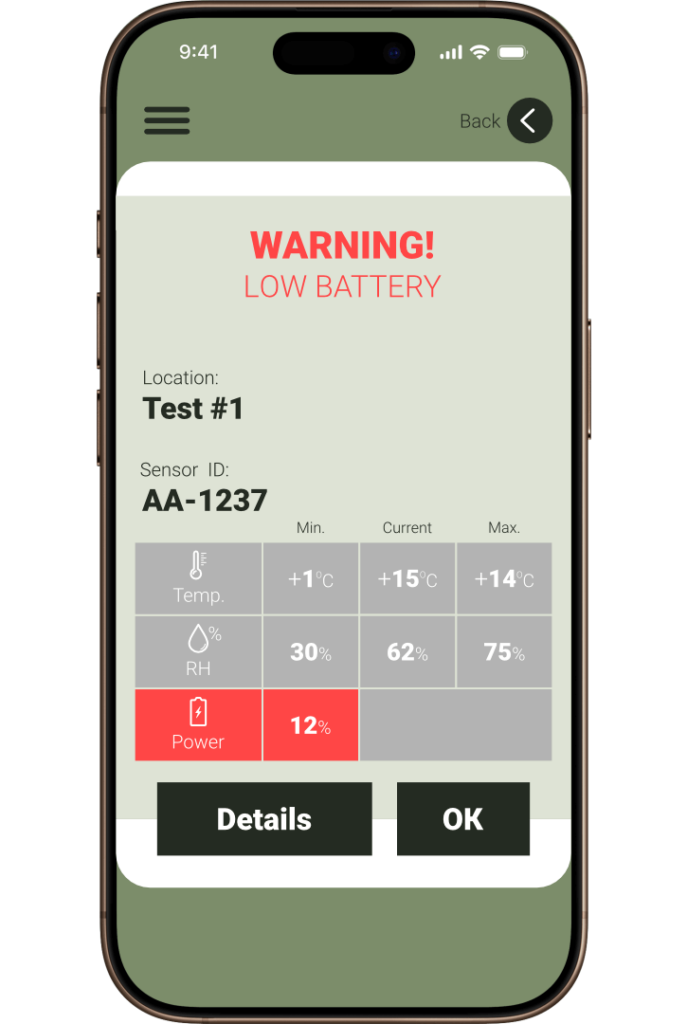

Secondly, the program also tracks battery levels for all connected devices. When the charge drops below the user-defined threshold, a notification is sent to the mobile application. If the temperature conditions in the warehouse do not allow for battery usage and the devices are powered by the mains, these parameters and notifications are not displayed.

Thirdly, the application collects and analyzes historical sensor data and generates graphs, showing temperature and humidity trends over specific time periods.

Lastly, the cloud application allows for assigning unique tags to each sensor with additional information, such as its location in the warehouse, model, etc. This information can be viewed in the mobile application, including when receiving notifications (by pressing the “More details” button).

Mobile Application Development

The team created a cross-platform mobile application supporting Android and iOS for displaying the information to the users.

The app allows users to connect and disconnect sensors by switching them to pairing mode and scanning their QR codes with the app. The data is then transmitted to the hub that connects the corresponding sensor to the network.

The main screen of the app shows the list of all connected warehouses (if there are more than one registered in the system) and their average temperature and humidity readings in real-time. One can also access the individual menus of each warehouse and see the corresponding readings from each sensor, the value limits, and the battery levels.

When sensor readings exceed or fall below the defined thresholds, the app displays corresponding notifications to the users.

Lastly, the app also shows real-time data in the form of graphs.

The Scope of Work

- Programming the central hub

- Cloud application development

- Cross-platform mobile application development

- Server configuration

Technologies Used

- Raspberry Pi 3/4 was used as the central gateway.

- The software for the hub was created in C++.

- The cloud application was developed in Java and Go, using the Jmix framework.

- The mobile application was developed in C++, using the Qt framework.

- The team deployed a VPS server.

Result

The solution developed by the Integra Sources team consists of temperature and humidity sensors, a central hub, a cloud application for system configuration, and a mobile application for real-time data display. The system allows for monitoring indicators and receiving automatic notifications if the values exceed set limits.

Similar temperature and humidity monitoring systems can be used not only in agriculture but also in any enterprise that requires maintaining a specific temperature and humidity level.

The customer plans to further enhance the system's capabilities to allow for automatic (using predefined scenarios) or manual (using the application) management of the warehouse's climate control subsystems.

The solution allowed the customer to:

- Minimize the risk of product spoilage and financial losses caused by non-compliance with storage conditions. Test results demonstrated a significant reduction in crop losses, ranging from 30% to 40%.

- Improve product quality by maintaining optimal climatic conditions.

- Receive timely notifications in case of deviations from set parameters, ensuring a swift response to emerging issues.

Budget

Duration

You might also like...

Firmware Development for Augmented Reality Glasses

The team improved the customer’s firmware for augmented reality glasses by developing drivers for the displays, accelerometer, and gyroscope of the device.

LEARN MORE

Software for EEG System

The Integra Sources team developed energy-efficient embedded software and an SDK for a medical EEG system. We delivered robust data transfer and storage, implemented multitasking on FreeRTOS, and improved connection security.

LEARN MORE